PacketMicro Delta-L Probing

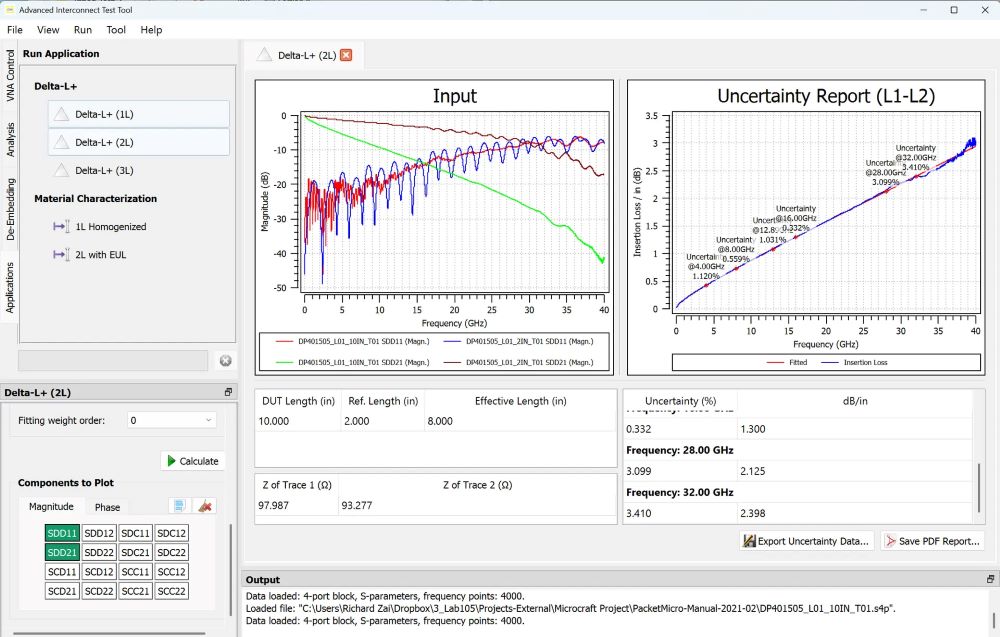

Intel's Delta-L methodology for printed circuit board (PCB) characterization is a technique for accurately measuring the loss per unit length of high-speed signal traces:

Key Principles:

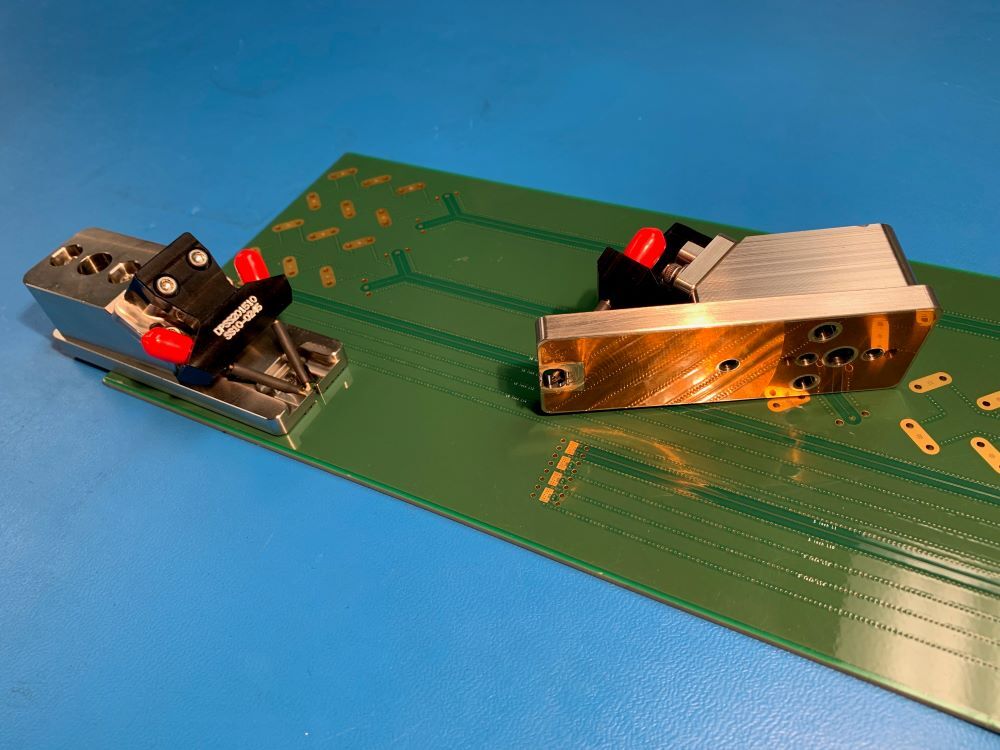

- Test Coupons: The methodology uses test coupons, which are small sections of a PCB with transmission lines (traces) of different, known lengths (e.g., a 2-inch trace and a 5-inch trace).

- Differential Measurement: A vector network analyzer (VNA) or similar equipment is used to measure the S-parameters of each trace. The measurements will include the loss from the trace itself, as well as the parasitic losses from the test setup (probes, vias, etc.).

- Subtraction & Division: By subtracting the measurement data of the shorter trace from the longer one, the effects of the test fixtures are mathematically "de-embedded" or removed. The remaining difference in loss is then divided by the difference in trace length, providing the true, per-unit-length loss of the PCB material and trace geometry.

Benefits:

- Efficiency: It's a straightforward and cost-effective way to get accurate loss measurements without requiring complex or time-consuming calibration standards like TRL (Thru-Reflect-Line).

- Material Validation : It allows for the accurate characterization of PCB material properties, such as the dielectric constant (Dk) and dissipation factor (Df), which are critical for predicting high-speed signal performance.

- Manufacturing Control :Manufacturers can use it to monitor process variations and ensure that the final product meets the design's electrical requirements.

- De-embedding :The method is an effective way to perform de-embedding, which is the process of removing unwanted fixture effects from a measurement.

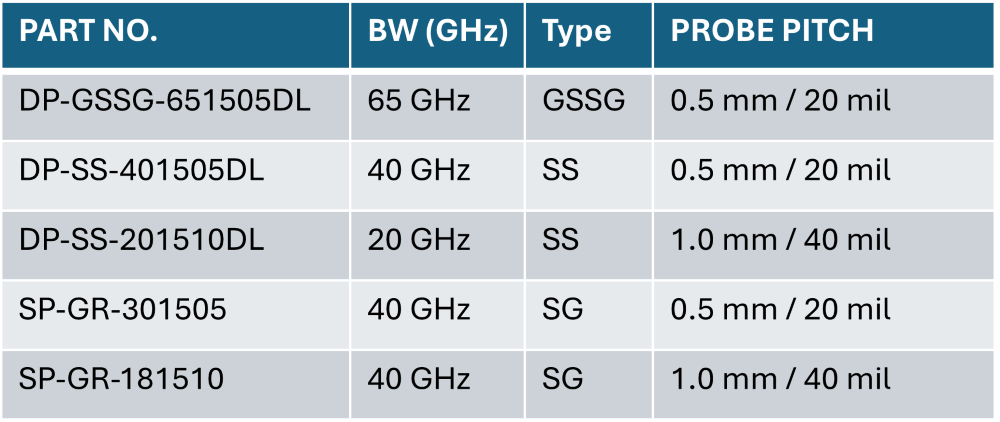

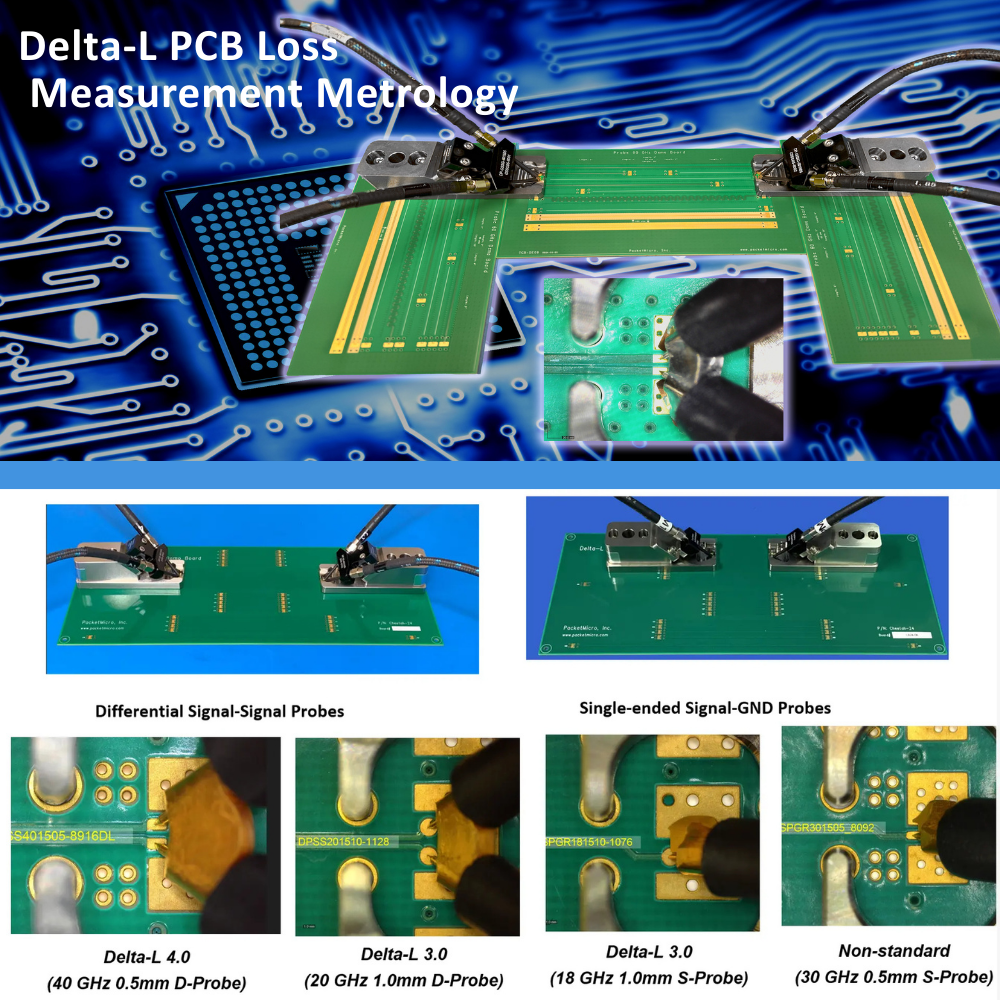

Key factors to consider while selecting a Delta-L probe:

- Bandwidth: The probe's bandwidth must be sufficient to accurately measure the frequencies of interest.

- Pitch: The probe pitch must match the pad geometry on your PCB test coupon. Delta-L 4.0, for instance, often specifies a 0.5 mm pitch for the probe pads.

- Physical Robustness: In a manufacturing or lab environment, probes are subject to a lot of use. A good Delta-L probe should be robust and durable to ensure consistent performance over a large number of connections.

- Repeatability: The probe's ability to consistently make the same electrical contact is paramount. Poor repeatability is a major source of measurement uncertainty in Delta-L.

- Insertion Loss: The probe itself will have some insertion loss, which can affect the raw measurement. A probe with low and well-characterized loss helps ensure the highest quality data for the de-embedding algorithm.

|

|

|

|